Keep ahead of the threat

Stay up to date with the latest mycotoxin information by signing up to our newsletter

Utilizing crop storage technology to reduce mycotoxin threat

Author: Josh Teulker, Alltech Mycotoxin Management

Click below to listen to the Mycotoxin Matters podcast episode with Josh Teulker hosted by Nick Adams. You can also hear the full audio or listen to the episode on Apple Podcasts or Spotify.

“There’s an app for that.”: A common phrase heard in everyday life. In the feed mill industry, we are often hesitant to incorporate new technology or let go of the manual control we have all grown to rely on at our mills. However, the last few years have brought new mycotoxin control technologies that are underutilized in our grain storage bins. But, incorporating them at each step of the grain handling process can provide valuable assistance in controlling mycotoxins in animal feed.

A clean bin is one of the most important first steps when it comes to crop storage and mycotoxin control. Traditionally, there has only been one method of cleaning a bin: an old-fashioned shovel and some elbow grease. With some investment in grain storage practices, manually cleaning a bin can be a thing of the past. Many companies have brought great products to the market that take the human out of the cleaning process. These will not only speed up the task, but investments in this type of technology also lead to enhanced safety protocols.

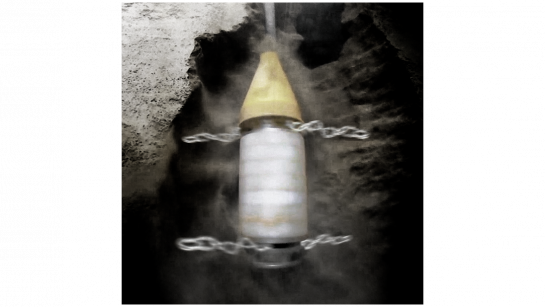

Installing such systems allows for the effective removal of crusted grains on the sides of bins, where mycotoxin-producing molds may have built up from past years’ grain storage. Through pairing no-entry cleaners with a high quality bin sweep, feed mills can almost eliminate the need for any employees to enter the silos.

In addition to physically cleaning the grain bins or silos, propionic-based products, such as Alltech’s Mold-Zap®, can be used to inhibit mold growth in stored grain. Mold-Zap can be used either in the feed mill flushing system or added directly to the raw materials.

(Picture of a Dual Impact BinWhip working to break crust inside a bin.)

Thorough cleaning pre-harvest is only one step in a successful mycotoxin control program. Testing incoming ingredients for mycotoxin levels allow feed mills to formulate necessary mitigation strategies, such as segregation or the use of mycotoxin adsorbents in the feed production process. Systems such as Alltech RAPIREAD®, a data management and analysis platform that is Neogen Raptor’s quick test device, allows feed mills and producers to test individual ingredients and understand the mycotoxin threat in less than 15 minutes. Alltech RAPIREAD is suitable for testing for seven of the most commonly found mycotoxins, while Alltech 37+® works as a complement and can identify up to 54 different mycotoxins. In addition to understanding the mycotoxin levels, these testing platforms are also designed to assist producers in understanding what impacts the mycotoxin levels can have on various species while also informing decisions on the steps required to reduce the mycotoxin threat.

Now that the storage bins have been cleaned and incoming grains are tested for mycotoxins, the next step is to find an effective way to monitor the grains being stored. There are many new sensor-based technologies on the market that facilitate remote monitoring. These sensors can observe almost every aspect of the bin and allow for aeration control from a phone app, essentially allowing mills to always understand what is going on inside their bins around the clock. If that is not enough for you, there are new products coming to market that can act as an employee inside a grain bin. Robots that crawl around a storage bin, break up clumps of grain and monitor the environments inside the bin. Are robots the future of grain bin monitoring? This is still uncertain, but there are some eye-catching innovations just around the corner.

(AGI’s SURETRACK bin monitoring system)

(The newly introduced Grain Weevil Robot navigating around a grain bin)

Are any of these technologies crucial to successful bin management and mycotoxin control? Of course not. However, as these types of technologies get more dependable, easier to use and affordable, adopting them for more efficient and effective storage will be immensely beneficial for mills going forward.

At Alltech, we offer a Mycotoxin Feed Mill Assessment to help customers with all aspects of mycotoxin management at the feed mill. The assessment looks at the mill’s receiving practices, sampling guidelines, testing and storage practices to help ensure it has an adequate program for controlling the mycotoxin threat. For more information on how our feed mill program can help you, please contact Josh Teulker at jteulker@alltech.com.